The pit was expected to produce between 5000-7000t, grading at about 5gpt.

Classic Minerals' Kat Gap gold project has an inferred resource of 975,722t tonnes grading at 2.96gpt, for 92,869oz.

The company processed the gold through its Gekko gold processing plant, which has a 30t pher hour capacity.

The Australian made Gekko processing system uses a transportable modular design that is scalable and well suited to Kat Gap's mineralisation.

Classic Minerals chairman John Lester said the company was on track to build and mine at full capacity by the end of July.

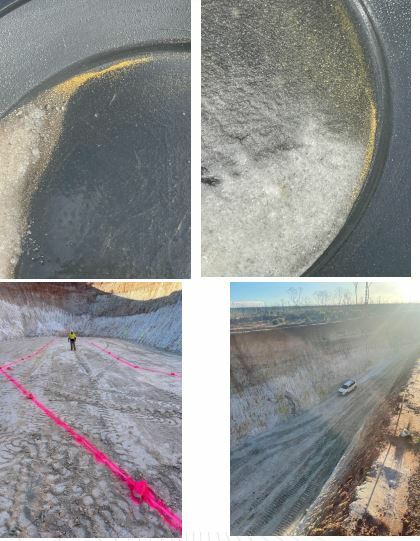

As part of the bulk sample mining campaign ore was mined in 2m thick layers, or flitches.

In a release to the Australian Securities Exchange, Classic said total production of waste and ore was 48,970t, with waste and ore stockpiled separately and all topsoil stored for future rehabilitation.

The ore zone at Kat Gap comes within 6m of the surface, and this was mined down to a depth of 15m and over a strike length of 50m.

Classic said both footwall and hanging wall contacts were very clear, which made it easy to extract with minimal dilution.

The company is awaiting final metallurgical test results on the oxide samples from the bulk sample, which will help in final pit design work.

Ore marked out at 14m below surface. Panned gold at the 14m level.