Enterprise Performance Management

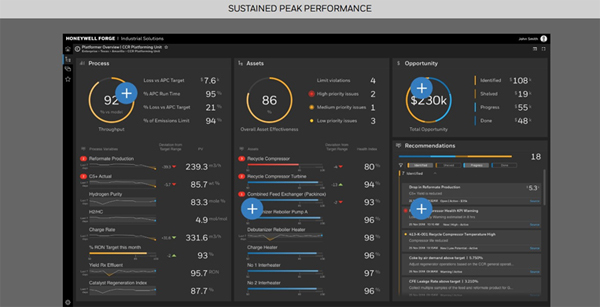

Honeywell Forge for Industrial provides actionable recommendations, highlighted with potential economic impact for intelligent business and operations. The portable and extensible software solution uses process and asset digital twins, role based, and comprehensive analytics to enable top to bottom enterprise-wide visibility improving decision making and sustaining overall performance of the process, assets, people and safety.

- $7M annually from optimization recommendations

- $3M annually through energy savings

- $1.2M annually from process efficiencies

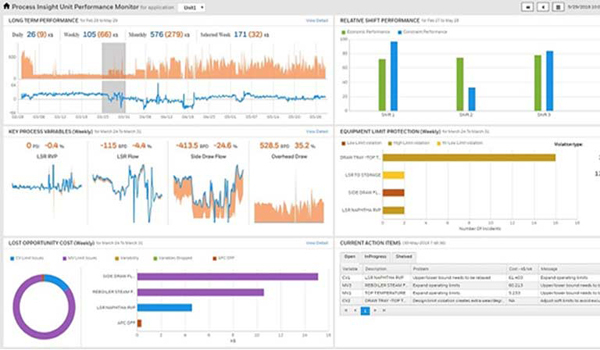

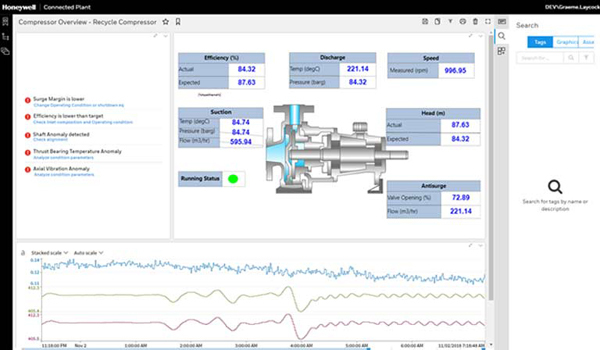

Honeywell Forge Process Reliability Advisor

Leveraging COP Process models with our extensive process experience, the Reliability Advisor evaluates your unit's performance to operate closer to constraints, and diagnose and mitigate issues. With this level of insight, you can improve process reliability — which means better production yields and equipment health, and other parts of your facility can operate with the greatest efficiency

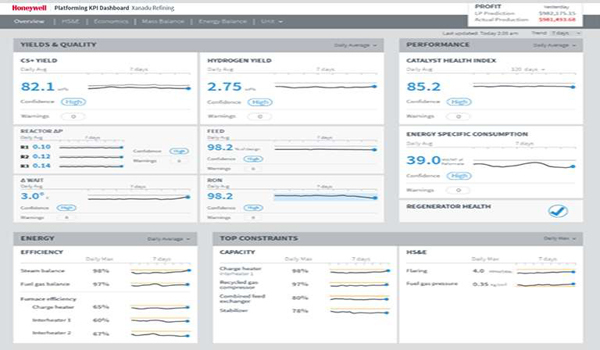

Honeywell Forge Process Optimization Advisor

The Optimization Advisor rigorously simulates an entire complex of process units to determine the maximum profitability of the complex, given current constraints and market conditions. To reach the optimum performance, operational recommendations backed by CIOP expert analysis are provided to help you reach optimal performance and asset utilization

Honeywell Forge Profit Performance Monitor

Cloud-based performance monitoring enables collaboration to understand what is limiting APC from driving the unit to its best potential

Provide visibility into the economic consequences of plant process performance as cost of lost opportunity Ensure sustainable benefits over varying operating conditions, visualizing real time unit profitability

Honeywell Forge Asset Performance Management

Cloud-based digital twins drive real-time equipment performance modeling and predictive analytics

Integrated process and asset models reveal root cause of bottlenecks, identify new levels of untapped productivity, and uncover potential problems

CASE STUDIES

Its integrated and collaborative operational model has achieved unprecedented continuity of operation. Codelco has fine-tuned production, improved the use and availability of equipment and systems, lowered costs, and significantly improved the productivity of their teams

Leveraging cloud-based analytic technologies, a Honeywell internal initiative boosted productivity of machinery and processes running within its Performance Materials and Technologies (PMT) division. The pilot program proved successful beyond expectations, having increased machine uptime as expected, yet doing so quicker than expected over a 6-month period.

LEARN MORE

Retiring knowledge leaves you needing to do more with less staff Digital Twin technology can help with embedded expert knowledge to make more assets smarter

Do more with your digital twin

The Industrial Internet of Things (IloT) promises to be most disruptive influence on automation systems since the advent of the microprocessor-based DCS

Are you ready?

The challenge today is going beyond conventional monitoring to find the right balance between asset availability and performance for better productivity.

ABOUT THIS COMPANY

Honeywell

Honeywell is a Fortune 500 technology company providing industry-specific solutions, including control technologies, products, and services for buildings and industrial facilities. Our technologies help mines and mills, supply chains, and workers become better connected to make our world smarter, safer, and more sustainable. Honeywell provides solutions for the digital transformation of operations, including software products and services and industrial cybersecurity solutions designed to help mining and minerals companies use operational data to drive insights that help improve processes and empower workers. We help improve safety, sustainability, and productivity with intelligent, autonomous operations and help you take digital transformation and industrial cybersecurity to the next level.

HEAD OFFICE:

- 715 Peachtree Street NE Atlanta, Georgia 30308

- Website: www.honeywell.com/