Drilling in the mining sector has been lagging in terms of using high-tech tools to improve performance, save time, and reduce costs, notably compared to the oil and gas industry.

Krux Analytics Inc. has developed an enterprise-level software platform to change the trend. Its revolutionising software allows drillers to capture, review field data, optimise drilling performance and communicate with their mining clients. At the same time, mining companies can track their drilling programmes in real time and have increased visibility on their operation and costs.

By connecting operational data and financial performance, miners and drillers use these new insights to not only effectively plan and budget for each site or project, but across their entire organisation using built-in analytics," reported the Canada-based company which also has an office in Perth, Australia.

Jody Conrad, President and CEO, founded Krux in 2016 in Calgary. A mechanical engineer with 20+-year experience drilling in the oil and gas industry, she rapidly saw the gap that could be improved in the mining space when it came to drilling.

Jody Conrad, Krux Analytics' Founder, President and CEO

"The core issue in the mineral exploration industry is that people are still using paper and Excel spreadsheets which don't provide a normalised or digital dataset," Conrad pointed out.

"Therefore, we are working on digitising and normalising their data so we can evolve into the instrumentation and real-life data," she explained.

Drillers on site use the KruxLog app where they can log their information, even in remote areas without Internet access during each shift. They can enter daily drilling activities, timesheets, survey results, and automatically submit reports to drilling supervisors. Supervisors can then submit reports to their clients for approval and run invoicing in minutes.

Instrumentation pilot project

Krux is currently working on a pilot project, KruxDAQ, which is expected to bring modernisation in drilling to the next level.

"KruxDAQ collects real-time instrumentation data from the drill to be used in conjunction with geological data and imagery to target efficiencies, optimise performance, improve data-based decision making and improve the bottom line," described the company.

Normalising the data is the starting point for Krux and also the most challenging task as nowadays this data is set in many different ways in the mining space, each company having its own way to manage it.

At present, all data generated during drilling in the mining sector is manually entered by the driller in an app. That includes various information such as how long the drill lasted, how many meters were made or the amount of time spent on a specific task.

"It is still a human telling you what they did," Conrad underlines. "The aim is that, at the end, the drill itself is telling us what it is doing in order to get real-time accurate results while you are drilling."

"Eventually, we do not want to have drillers entering anything in the app. The idea is starting to take shape by removing as much of the manual human component as possible," she added, pointing out that "drilling instrumentation data offers some insightful information about operational performance and what is in the ground".

For that to happen, it requires that the drill is fully instrumented. The equipment needs to have the instrumentation, the configuration and the communication methods to talk to Krux.

The company explained that active pilot projects are successfully collecting two data points per second for values such as instantaneous rate of penetration, weight on bit, depth, torque, water/air pressure/flow, etc.

In addition, engine monitoring and gas detection can provide data for Environment, Social and Governance (ESG) reporting such as fuel/ water consumption and Greenhouse Gas (GHG) emissions released during the drilling process.

Cost of instrumentation coming down

Drilling instrumentation is rather common in the oil and gas industry as more capital has gone into drilling in that sector. But in the mining sector, significant development must still take place as technology adoption has been lagging in comparison.

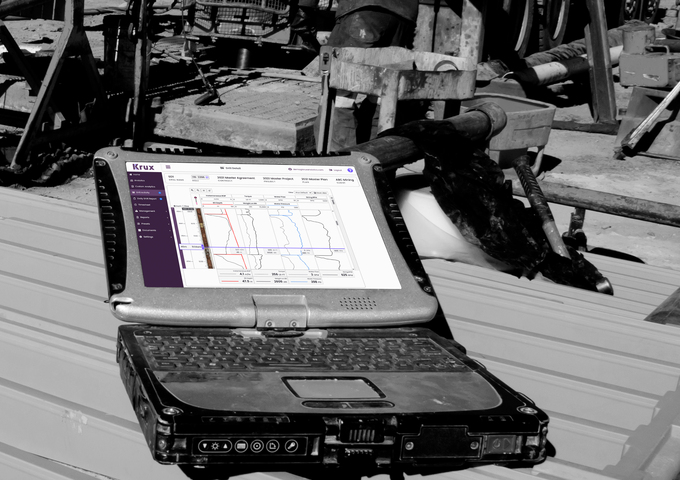

KruxDAQ: Visualisation of instrumentation data

Conrad believes "it is the ideal time to get into that market as the cost of instrumentation is all coming down and it is now affordable to get into the mineral space".

"It is in the making. It is not something that someone could subscribe for tomorrow. But they can learn more about it or potentially even be included in the pilot project," explained Conrad.

"We have already successfully instrumented a drill and we are now able to collect data points. We are now working on the beta version of the software which should be finalised and released in Q2 2023. It will be ready for consumption for anyone who has the instrumentation", revealed Conrad.

According to the company, "Krux envisions with the addition of the real-time drilling instrumentation dataset alongside geological data and imagery will provide users the ability to build predictive models for required drilling energy, optimal drilling parameters, bit type, rock hardness, geotechnical indications, and so much more".

ABOUT THIS COMPANY

Krux Analytics

Krux Analytics created an industry-leading software that makes data collection simple, displays it in easy-to-understand dashboards, and provides advanced analytics that takes the guesswork out of improving operations.

HEAD OFFICE

- Address: Suite 500, 1015 4th Street SW, Calgary AB T2R 1J4, Canada

- Tel: +1 855 752 7258

- Email: info@kruxanalytics.com

- Web: www.kruxanalytics.com

SOCIAL

LEADERSHIP

- Jody Conrad, Founder, President & CEO