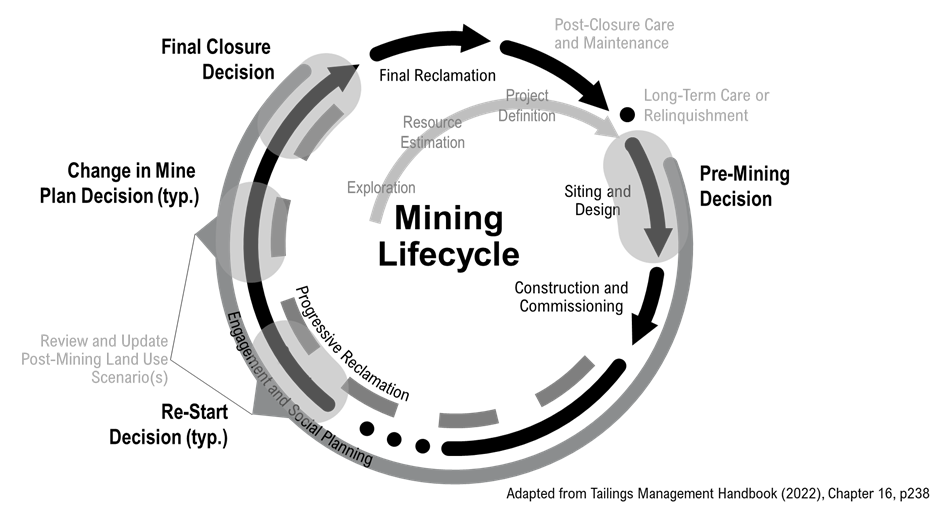

The modern model of the mining life cycle (Figure X) begins at exploration and extends through the post-closure phase period. Understanding this cycle is essential not only for managing financial risks, but also for promoting long-term environmental stability and supporting the socio-economic resilience of communities. Best practice today integrates mine closure considerations during mineral resource characterisation, conceptual mine planning and full-scale operations. The goal is more effective, efficient and sustainable outcomes during and after mining activity.

Early life cycle: exploration to feasibility

The early phase of a greenfield mining project involves geological exploration which, if promising, leads to mineral resource estimation. This is, in turn, followed by the scoping study, the first time the project proponent defines the potential scope of a development project.

The scoping study outlines a conceptual operational plan, including preliminary closure scenarios. Although the scoping study is not the final word on closure, it provides a foundation upon which more detailed and credible plans can be built. This integration continues during the pre-feasibility study and feasibility study, where both operating strategies and closure designs are refined to reflect realistic technical, environmental and socio-economic conditions.

The feasibility study must also consider the physical and chemical stability of final landforms, the long-term use of infrastructure, and the requirements for stakeholder engagement. Closure planning at this stage lays the groundwork for effective implementation later and reduces the likelihood of expensive redesigns or remediation measures at the end of the mine's life.

Development and operations: embedding closure

Once a project is sanctioned, the mining life cycle progresses to detailed engineering, procurement, construction and then into the operating phase. Historically, detailed closure planning did not begin until the later stages of operations, often just before final production. This approach, however, has proven costly and risky, especially in terms of social and community outcomes.

Deferring closure planning until the end can result in limited options, increased liabilities and missed opportunities for integrated, sustainable outcomes. Experience across the industry increasingly shows that closure must be embedded into operational planning. This includes constructing tailings and waste facilities with closure in mind, incorporating progressive rehabilitation into annual work plans and maintaining transparent stakeholder relationships throughout the mine's life.

The transition to closure

As the end of production nears, closure planning must shift from conceptual strategies to detailed implementation. This stage involves not only the physical rehabilitation of land and infrastructure, but also complex social and economic considerations. Communities that have grown dependent on the mine for employment, services and infrastructure face a period of uncertainty and potential hardship.

This socio-economic transition cannot be effectively managed if it begins only at the end. Mining companies need to develop closure transition strategies well in advance, often several years before final production ceases. These strategies must be based on a deep understanding of community dynamics, dependencies and aspirations. Engagement must be proactive, inclusive and sustained.

Transition strategies may include retraining programmes, support for local enterprise development, and phased handover of social infrastructure. Although it may not always be possible to fully replace the economic contribution of a mine, practical efforts to mitigate the impact of closure are expected – and increasingly required – by regulators, investors and host communities alike.

Post-closure obligations: the long tail

Following final closure activities, mines enter the long-tail post-closure phase. This period may extend for decades and involves a range of legal, technical and social obligations. These can include environmental monitoring and maintenance, water treatment, landholding costs and continued community engagement.

Post-closure obligations are not limited to regulatory requirements. They also include informal but powerful expectations created through years of engagement with external stakeholders, be they governments, community leaders or civil society organisations. Failing to meet these expectations can result in reputational damage or even legal action. Moreover, in many jurisdictions, relinquishment is difficult to achieve. This means mining companies can face long-term financial obligations that extend well beyond the productive life of the operation.

Legacy sites and re-entry into the cycle

Legacy mine sites, in contrast with greenfield or brownfield sites, enter the mining life cycle at the post-closure phase, usually after a long period of minimal care and maintenance, if any. These sites require reassessment in terms of regulatory compliance, environmental risks and stakeholder expectations. Often, the technical and financial challenges of managing legacy sites are far greater than if closure had been integrated from the outset.

SRK Consulting's experience in managing such sites underscores the need for strong technical understanding, robust risk assessment and open communication. Rehabilitating legacy sites is possible, but rarely efficient. This highlights the strategic value of life cycle-based closure planning.

Economics of closure

The conventional approach to mine project development relies on decision-analysis and valuation processes, with discounted cash flow (DCF) methods guiding greenfield projects through trade-off studies and investment reviews. DCF methods reduce the present value of future revenues and costs, including closure and post-closure obligations. However, relying solely on DCF outputs can underestimate the financial impacts of closure.

The limitations of traditional DCF are well-documented. Emerging variations, such as undiscounted cash flow analysis, hold promise for more accurately assessing closure costs. This method assumes a 0% discount rate, treating all costs and revenues equally, regardless of timing. By removing the discount factor, the financial significance of closure costs becomes clearer.

A scenario-based approach to DCF allows for the incorporation of operational decision points during the active mining phase, such as suspending operations, restarting, or adjusting mine plans. As the mine nears closure, the financial burden of closure and post-closure obligations increases relative to the mine's revenue.

Circular economy and closure

Circular economy principles present new opportunities for closure planning. Reduced and near-zero-waste mining approaches are being explored across the industry, with promising implications for both environmental performance and economic value.

In some cases, processed materials can be reused or recycled. For mines with downstream processing capabilities, the potential for material recovery and re-use is higher. However, large volumes of material, limited local demand and transport costs can limit practical application.

Nonetheless, if supported by early planning, circular economy approaches can contribute to sustainable closure strategies. They also offer opportunities to build capacity in local communities.

Future pathway

Integrating closure into the mining life cycle is now essential. From exploration to post-closure, each phase presents opportunities to embed sustainable thinking, reduce liabilities and contribute to positive outcomes.

Early planning, technical integration, financial realism and stakeholder partnership are the cornerstones of successful closure. Companies that adopt this approach are best positioned to meet future challenges and leave a responsible legacy.