ESCO® buckets for mining excavators are custom engineered to match the required capacity and duty cycle for each application. Choose from standard or fully customized wear packages.

ESCO mining hoe buckets are performing at hundreds of locations on 6 continents. A proven performer that keeps machines operating with excellent reliability and significantly less maintenance.

Enhanced Productivity

- Optimized payload by engineering to site material density while striking a balance between maintenance requirements versus capacity

- Increased machine availability using high-strength steel fabricated to exacting specifications to reduce the chance of unplanned maintenance

- Industry-leading Nemisys® lip system and GET provides unmatched reliability and service life with maximum weight efficiency

Reduced Maintenance

- Enhanced beam shapes, configuration and weld-joint design using advanced finite element analysis (FEA) tools distributes operational stresses for increased durability

- Lower maintenance costs by site tailored wear protection proven to lower GET cost of ownership overcompetitive systems

- Fewer and faster wear parts replacement with the reliable Nemisys® GET that maximizes wear metal utilization with ESCO premium alloys and easy-to-use integral hammerless locks

|

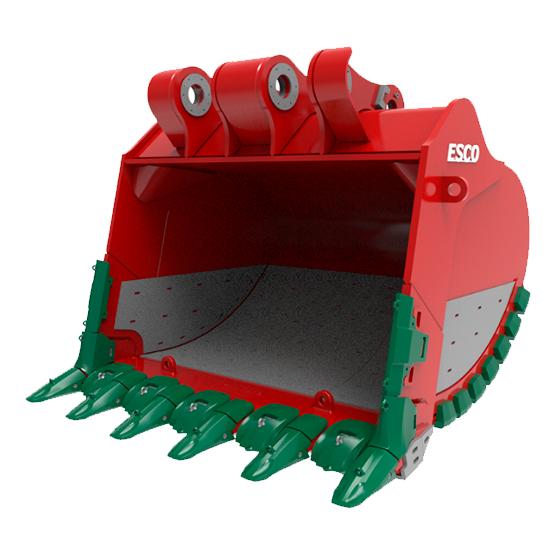

ESCO HD Mining Class Hoe Bucket ESCO HD buckets were developed as an economically viable product for tough mining applications - reducing customer investment while still providing excellent performance. The single beam configuration is reinforced with unique interior gussets and longer lug plates that provide optimum strength to eliminate deformation in demanding mining applications. Corner gussets reduce stresses in the transition from the beam to the side stiffener. The result is a bucket that provides excellent productivity and reliability in most mining applications.

|

|

|

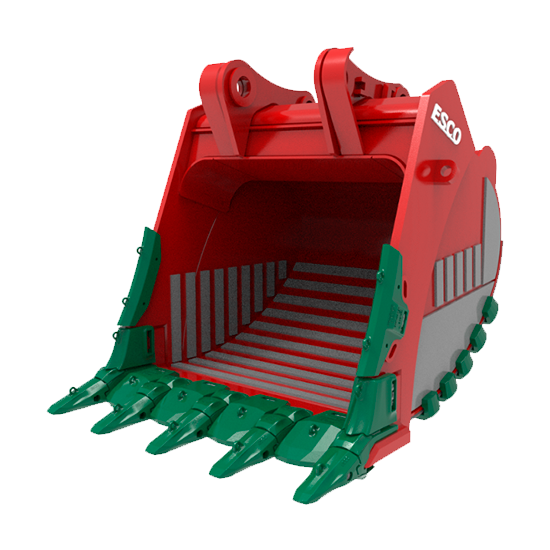

ESCO XHD Mining Class Hoe Bucket ESCO XHD Buckets are a dual-beam configuration designed for the toughest mining applications. This extra heavy-duty bucket has been used for years and is field-proven in mines and quarries worldwide. The XDPM bucket is the top choice for severe applications with extreme impact and abrasion. Complete wear protection options are also available to ensure maximum life and productivity. ESCO engineers provide expert technical support to ensure customers select the best wear package to maximize life and productivity in their application.

|

|

Lower your cost per ton with the Nemisys® system

|

With over 1000 installations worldwide, ESCO Nemisys lip and GET system is field proven to lower operating cost per ton. The Nemisys system features hammerless installation and removal, superior alloys for optimum strength and wear life and reduced component/system weight to reduce stress on equipment and maintenance personnel. The Nemisys system ensures your equipment operates with maximum productivity and profitability.

|

|

- Offers flexibility with differentiated design segments to meet application requirements

- Provides field-proven strength, wear life, productivity, and ease-of-use

- One of the best hammerless locking systems in the world for mining GET

ShovelMetrics™ - A complete monitoring solution for excavators

Motion Metrics™ ShovelMetrics - Gen. 3, powered by proven machine learning algorithms trained on two decades of mining data, provides accurate and reliable information in the toughest mining environments. More than 80 mines worldwide trust ShovelMetrics to increase safety and operations productivity.

Now available with industry-leading 3D imaging technology to bring you the most advanced excavator monitoring service on the market. With support for all types of shovels, excavators, and backhoes, ShovelMetrics Gen. 3 is a fully managed shovel monitoring service, including:

- Tooth wear monitoring

- Missing tooth detection

- Particle size analysis

- Payload monitoring

- Blind spot reduction

ABOUT THIS COMPANY

Weir – ESCO Division

A global leader in mining buckets and GET with innovative product design, state-of-the-art manufacturing and metallurgy expertise.

HEAD OFFICE:

- 25 Trade St., Lytton, QLD 4178

Phone: +61 7 3004 4100

Email: brisbaneinfo@mail.weir

Website: www.esco.weir